Monolithic Multi-Port Nylon

After the nozzle blockage and explosion of the last attempt, I've converted the fuel grain to a single piece of nylon, so none of it can fall down. I realised as I was fitting it to the stand, that I had taken no pre-firing pictures of the fuel, but once I'd got that far, I wasn't going to dismantle the engine to do that. You'll have to imagine what it looked like from the post-firing pictures below. I found a bar of nylon with outside diameter 18.5mm which slips nicely inside the PVC pipe. I used end-plugs of split and re-closed PVC pipe to form pre- and post-combustion chambers around a 35mm fuel grain, the same as I did for the grain made from the nylon tubes. I could only get 12 holes through the nylon, rather fewer than with the separate pipes, so I made the grain slightly longer. I also tried to get the nitrous oxide to flow down the outside of the grain, between the nylon and the PVC, by castellating the end-plugs, to give the gas a route into the gap, to get even more area exposed.

The motor burned nicely, slightly sub-optimal in a couple of minor details. I had to get a new nitrous inject/piercer after the previous one blew up. This new one (not from Eclipse this time) was not so well made as the one I bought from there originally, and it had two related flaws. The injector hole did not pass perpendicularly through the body of the injector, but came through at an angle to the axis. And, because the hole was also not quite on the axis either, the piercer was not sufficiently strong to hold up against the steel of the gas bottle. It did manage to pierce the end of the bottle, but the injector hole closed up slightly as it did so resulting in a slower oxidiser delivery and longer burn time.

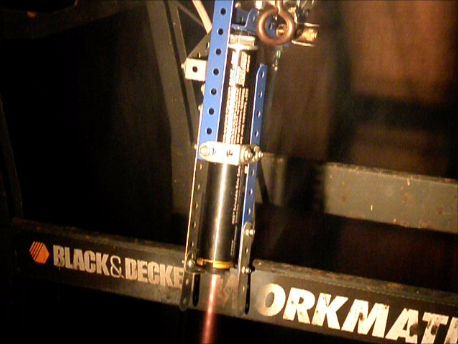

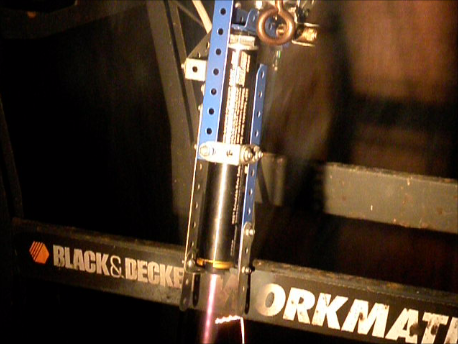

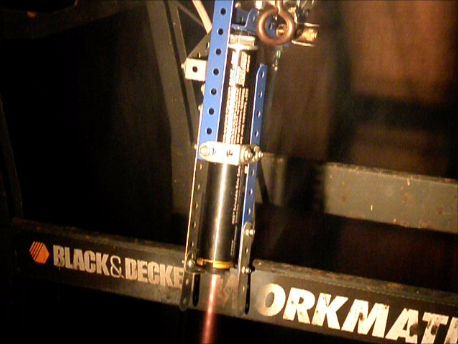

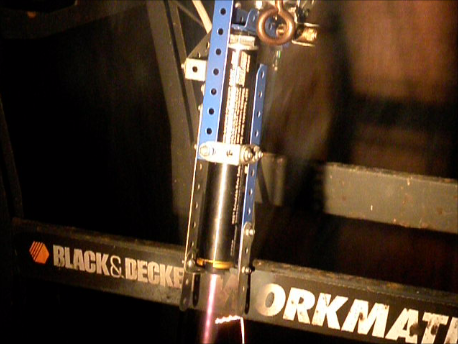

I managed to isolate a few frames where you can see Mach diamonds in the exhaust flow,

I didn't manage to record the thrust at all this time, even the dodgy video of the scales method. But I anticipate the thrust to have been fairly low, because of the restricted oxidiser flow and extended burn time.

Each of the holes in the nylon has opened up by a similar amount from about 2mm to about 3mm ID. The opening is more pronounced at the forward end of the fuel grain. (When I get back in to work I will re-weigh the grain to see how much mass has been lost. My initial estimate is about 1.7g, which is a good fraction of the 2g I was aiming for). The opening is fairly similar comparing the peripheral to the central holes.

The misaligned injector directed the oxidiser flow into the wall of the pre-combustion chamber and resulted in it burning all the way through at that point, including through the paper wrapper. This is the first time the combustion has reached the aluminium wall in any of the tests. Fortunately it came out unscathed; or at least the anodising on the inside of the tube is still intact, so whatever erosion there was cannot have been very much.

.jpg)

.jpg)

.jpg)

This grain seemed to work well, and with a better injector would have been very good. But it was very difficult to produce. What I need is an extrusion that is near enough to this kind of design, without paying for my own die. I'm on the look out for anything already in production for a “real” application that I might be able to scrounge some of.